Documentation

Measure twice, cut once...

Documentation

3D CAD

Lofting the project and creating parts and assemblies is accomplished using SOLIDWORKS. Assemblies are created and populated with part files. A product data management system within the CAD program can be used for off-site collaboration. Revisions can also be tracked. Bills of material are generated with all parts, manufactured or purchased.

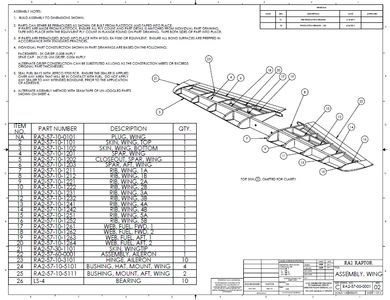

Electronic Drawings

Drawings are generated for parts and assemblies and then released to the manufacturer. Assembly drawings are comprised of the assembly bill of material as well as dimensions, tolerances, and notes to manufacture. Part drawings identify materials, layup schedules, dimensions and tolerances as well as the finish required to make the part.

Report Generation and Testing

One test is worth a thousand engineering reports...

A report is generated after each phase of design. The report typically identifies references, design loads, material design properties for the parts, the analysis results, and a copy of the drawing package. The report can also layout a logical test plan to validate the design and analysis.

Creative Flight Designs, LLC

Copyright © 2023 Creative Flight Designs, LLC - All Rights Reserved.

Powered by GoDaddy Website Builder

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.